|

With the BK-938 you get a cheap second soldering iron for easily solder your SMD components on their copper surfaces. But is this soldering iron worth its twenty euros? |

Introduction to the BK-938

Various brand names, various type numbers, various prices

As often happens with this kind of Chinese bargains, you can find the same device for very different prices under different type numbers and with different manufacturer logos on the Internet:

- U-938

- BAKU BK-938

- DKT 936I

The BK-938 is delivered from € 20,00 in a neat box and internally protected by a sheet of plastic foam, your order survives the rather rigid Chinese way of shipping.

|

| The BK-938 is delivered in a neat box. (© 2018 Jos Verstraten) |

With its dimensions of 5.5 cm width, 8.5 cm depth and 5.0 cm height, the device looks very cute. On the front is a professional ON/OFF switch and a rotary potentiometer for setting the temperature of the soldering iron. With its length of 16.0 cm, the soldering iron lies comfortably in the hand and is connected to the station via a standard tulip plug. Only two wires are connected, it is clear that there can be no automatic temperature control.

The BK-938 is supplied with one soldering tip with a length of 3.4 cm. The tip is clamped around the heating element with a spring and is easy to replace.

|

| The soldering station BK-938. (© Aliexpress) |

To give you an idea of the dimensions of the tip, we have kept that tip on one of the connections of an IC in a QIP-80A housing, see picture below. On this housing the pins are only 0.8 mm apart. As you can clearly see, assuming you use very thin soldering tin and have a very steady hand, you can approach the pins one by one without any problems.

|

| The tip of the soldering iron on one of the pins of a QIP-80A housing. (© 2018 Jos Verstraten) |

- Mains voltage: 230 Vac or 110 Vac, please note when ordering!

- Power supply soldering iron: 12 Vac

- Power soldering iron: adjustable between 1 W and 18 W

- Temperature pin: adjustable between 50 °C and 450 °C

- Warm-up time: less than one minute

- Length cable soldering iron: 75 cm

The BK-938 on the test bench

The electronics of the BK-938

We were very curious about the electronics of this soldering station. The picture below shows that there is not much technology in it. A small mains transformer and a small PCB, that's all. You can see that the secondary winding of the transformer is directly connected to the RCA tulip connector. The power is therefore regulated on the primary side of the transformer. What is immediately noticeable is the carelessness of the wiring. The mains cable has no strain relief, the secondary winding wire is poorly insulated and can easily make contact with the transformer core, etc.

|

| The contents of the housing is pretty sloppy wired. (© 2018 Jos Verstraten) |

It is obvious to assume that regulating the power supplied to the soldering iron is done via a simple phase cutting control. The in phase cutted mains voltage is connected to the primary winding of the transformer. After disassembling the PCB, this assumption appears to be correct. One high-voltage capacitor, two resistors, a diac and a 0.8 A Motorola triac of the MAC97A type.

|

| The electronics: a simple triac phase cutting control. (© 2018 Jos Verstraten) |

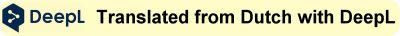

What does a secondary transformer voltage look like when it is primarily cut in phase? Not too bad, see the oscillograms below where the secondary voltage with connected soldering iron is shown from left to right for potentiometer positions 0, 5 and 10.

|

| The voltage on the soldering iron at three positions of the potentiometer. (© 2018 Jos Verstraten) |

In theory, nothing is simpler than measuring electrical power. Power is voltage times current, two ordinary universal meters are switched on and ready to go. This applies to direct voltages and pure sine voltages, but not to the strange voltage and current forms that arise during phase cutting.

Fortunately, we have two multimeters of the more expensive kind, which claim that they calculate and display the rms value when measuring voltages and currents. With these meters it must therefore be possible to measure the rms value of the power of the soldering iron. In the table below, the results are summarized for the potentiometer positions 0, 5 and 10. This is quite similar to what the manufacturer promises.

|

| The power of the soldering iron at three potentiometer positions. (© 2018 Jos Verstraten) |

For the three potentiometer settings mentioned above, the temperature at the tip of the soldering iron was measured with a thermocouple. The results are shown in the table below. The temperature range of 50 °C to 450 °C specified by the manufacturer is not achieved. However, the melting point of lead-free solder tin (99.3 % Sn - 0.7 % Cu) is between 217 °C and 240 °C. The tip becomes hot enough from position 5.

|

| The temperature of the soldering tip at three potentiometer positions. (© 2018 Jos Verstraten) |

And now the practice ...

We are satisfied with this soldering iron. However, the setting of the power could have been omitted. It makes no sense to set the dial to a lower setting than 10. Only in the highest position the station delivers enough power to the soldering iron to make SMD soldering after SMD soldering at a normal speed.

Note that the thermal energy stored in the tip is too small to do anything other than solder the pins of SMD components. Even soldering one wire of a 1/4 W resistor on a solder island of 3 mm diameter requires too much power. The tip cools down so fast that the tip stays stuck in the semi solidified tin.

In short: a nice gadget that is really useful from time to time.

BK-938 220V 18W Mini Soldering Station