Introduction to the ZD-99

Various names, manufacturers and prices

As is so often the case with popular Chinese products, this soldering iron is offered under various names by various 'manufacturers'. A selection:

- Zhongdi ZD-99

- Basetech ZD-99

- Basetech JLT-13

- Duratool DO1843

- Fixpoint AP2

- Velleman VTSS4

The label on the unit is conclusive. Manufacturer is Ningbo Zhongdi Industry from China. In Europe the device is distributed by TIPA from the Czech Republic.

Also what you have to pay for it makes a difference. An extensive search on the internet gave us a price range from € 12.62 to € 26.99 (price level August 2020). So it is worth to search on the internet. We bought a ZD-99 and so we will continue to use this name in the rest of this review.

Correcting a few misconceptions

The ZD-99 is advertised on most sites as a 'soldering station with adjustable temperature control'. The ZD-99 is absolutely no such station. With such a description, every electrician thinks of a soldering iron that is powered from a low voltage transformer. A soldering iron that also has a temperature sensor in the tip that ensures that the temperature of the tip remains constant and is quickly restored after each soldering.

In the 'soldering station' ZD-99 there is none of this. A small PCB contains a triac control that controls the 230 V mains voltage in phase and offers this voltage to the heating element. So the only thing that is controlled is the power offered to the soldering iron. And that is something very different from a temperature control!

So the ZD-99 doesn't deserve the name 'soldering station' but the name 'soldering iron'. That is why we will put the word 'soldering station' between quotation marks in the rest of this article.

The delivery of the ZD-99

The delivery looks professional. The 'soldering station' is packed in a sturdy box. The set comes with only one soldering tip with a tip diameter of 1.5 mm. Luckily you can buy other tips for a bargain price, read on.

|

| The packaging of the ZD-99. (© 2020 Jos Verstraten) |

In the picture below you can see what you get for your money. The actual 'soldering station' is 11.4 cm wide and 14.2 cm deep and weighs 460 grams. From the back comes the power cord with a length of 107 cm. This cable ends in an earthed mains plug. The mains cable is 5.5 mm thick and quite rigid. From the left side the cable comes to the soldering iron. This cable is 110 cm long, 5.5 mm thick and (unfortunately) just as rigid as the power cord. Under the holder for the soldering iron there is room for the sponge that takes care of keeping the point of the soldering tip clean.

The 'soldering station' is stable on six rubber feet.

|

| The 'soldering station' ZD-99. (© 2020 Jos Verstraten) |

The soldering iron is with its weight of only 66 grams quite light, but working with it is unfortunately hindered by the thick and rigid cable. The soldering iron is 20 cm long and has a maximum diameter of 22 mm at the grip. On that thickest part of the handgrip is a cushioned foam grip that ensures that the iron stays well in the hand.

The visible part of the soldering tip is quite small, only 20 mm. That could have been a bit longer! The diameter of the soldering tip is 1.5 mm at the point and 4.8 mm at the fixing nut. Between the handle and the tip is the 72 mm long metal cylinder that contains the heating element. What is immediately noticeable is that this cylinder is attached to the handle with three sturdy screws. A solid construction! The soldering tip is fixed in the cylinder with a nut. In quite a few reviews of the ZD-99 it is claimed that this nut is quickly loosened, but we haven't been hindered by that.

|

| The soldering iron of the ZD-99. (© 2020 Jos Verstraten) |

If you compare the appearance of the ZD-99 with that of the Weller WLC100, see the picture below, you will notice that both devices resemble each other like two drops of water. Also the WLC100 is wrongly sold as a 'soldering station', because also this soldering iron only has a simple triac control built in, which does not control the temperature, but the power. The WLC100 is mainly offered via eBay for prices around € 50.00.

|

| The expensive WLC100 from Weller, of which the ZD-99 is a clone. (© eBay) |

Four different soldering tips have been developed for the ZD-99, which you can find everywhere at very different prices. The codes of these soldering tips are C1-1, C1-2, C1-3 and C1-4. You are advised to order some extra soldering tips. As with all cheap soldering tips, the tips are slowly absorbed by the solder. The material of the tips dissolves a little in the molten solder and slowly but surely disappears to your solder joints. What is striking is that the tips are quite long. The part that is inserted into the heating element can therefore store a lot of thermal energy and deliver this energy to the point if you need to solder quickly in series, for example the sixteen pins of a DIL-IC.

|

| Dimensions of the four available soldering tips. (© 2020 Jos Verstraten) |

A very pleasant feature of the ZD-99 is that you can reorder the wear-sensitive parts separately for not too high prices. We have found it for you:

- Heating element: € 1.14 (DSM Components)

- Soldering tips: € 4.68 per set of four, € 1.17 each (Reichelt)

- Mounting nut: € 1.69 (Rabtron)

- Soldering iron: € 6.50 (Soldeerbout Shop)

However, replacing the heating element is a job that requires a lot of patience and 'Fingerspitzengefühl'!

|

| The individual heating element costs only € 1.14. (© DSM Components) |

The ZD-99 viewed from the inside

Unscrewing the housing

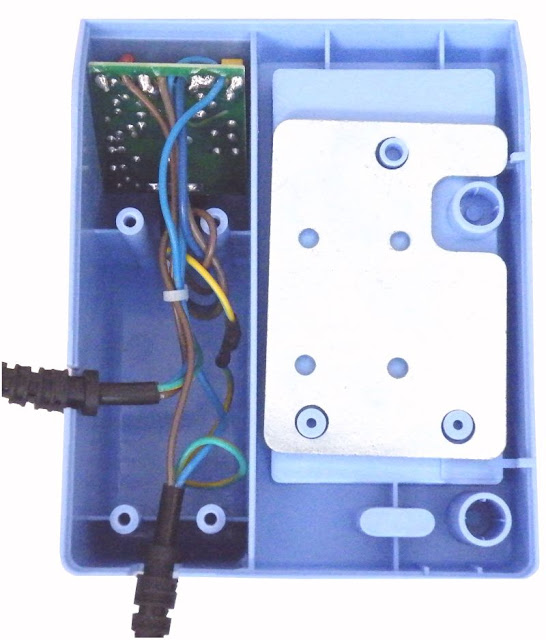

The bottom of the 'soldering station' has six rubber feet. Under four of these feet you will find the screws with which you can unscrew the housing. As the picture below shows, the internal is quite empty. Beneath the space for the sponge is a metal plate with the only conceivable purpose to make the whole thing heavier.

In the left compartment is the small PCB behind the front plate. From the wiring you can see that the ground wire of the power cord is directly connected to the ground wire of the cord to the soldering iron. So the soldering point of the bolt is earthed.

|

| The internal of the 'soldering station'. (© 2020 Jos Verstraten) |

In the picture below we merged the two sides of the PCB. It is clear that the schematic contains something more than a rudimentary triac regulation. There is even a form of interference suppression by means of an LC filter!

|

| The PCB with the triac-controlled phase control. (© 2020 Jos Verstraten) |

Mains-powered triac circuits have a pair of capacitors with a large voltage across them. These capacitors can break and cause a short circuit. It is therefore important that there is a fuse in the circuit. The ZD-99 does not have a fuse and that is a fact that the manufacturer of this 'soldering station' can be blamed. We strongly advise you to built a fuse holder with a 500 mA fuse in the housing. There is enough space for this, for example above the cord that goes to the soldering iron. Cut the brown wire of the mains cord and solder the two wires to the soldering lugs of the fuse holder. A small, inexpensive operation that can save you a lot of trouble.

|

| The built-in fuse holder. (© 2020 Jos Verstraten) |

The ZD-99 tested

The delivered power

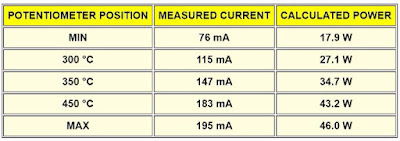

According to the specifications, the ZD-99 must be able to deliver a maximum power of 48 W. We have tested this by connecting a multimeter in series with the mains cord and measuring the RMS-current for different potentiometer positions. The results are summarized in the table below. The mains voltage was 236 V at the time of the measurements. The maximum power is 46.0 W. This is almost equal to the specified power.

|

| The power supplied for various potentiometer positions. (© 2020 Jos Verstraten) |

We looked at the voltage across the heating element in three positions of the dial: minimum, halfway and maximum. In the maximum position, almost the entire periods of the mains voltage are applied to the element. The flat tops of the sinuses are the result of core saturation of the isolating transformer connected between the mains and the soldering iron.

|

| The voltages across the heating element. (© 2020 Jos Verstraten) |

The rotary potentiometer has three calibrated settings: 300 °C, 350 °C and 450 °C. We have measured these temperatures by putting a thermocouple in good mechanical and thermal contact with the point of the soldering tip using heat-conducting paste. Afterwards we turned the potentiometer to the minimum position and to the three calibrated positions and read the temperature after fifteen minutes.

Because thermocouple measurements are notorious because of the large error percentages, we performed these measurements twice. The first time with our VC650BT multimeter with its own thermocouple, the second time with our TM-902C thermometer with its own thermocouple. The values in the table below are the averages of both measurements.

As you can see, the actual temperature of the soldering tip is well below the specified value. The question remains whether this is bad. The solder you usually use consists of 63 % tin and 37 % lead. This solder melts at 183 °C. The currently mandatory lead-free solder consists of tin, copper and silver and has a melting point of about 217 °C. However, there is no point in soldering at the moment the solder melts. The point of the soldering tip is then not hot enough to transport enough heat to the parts to be soldered. A good temperature for lead-containing solder is 350 °C and for lead-free tin 380 °C.

As the table shows the ZD-99 meets the minimum temperature requirement for both types of solder.

|

| The temperatures at the point of the soldering tip. (© 2020 Jos Verstraten) |

An important factor is how quickly a soldering iron reaches the desired temperature. Active soldering irons with a built-in temperature sensor and good temperature control are sometimes at the desired temperature after just one minute. It will be clear that passive soldering irons such as the ZD-99 take a bit longer. We measured this with the logger function of our VC650BT multimeter. The results are shown in the graph below. So it takes ten minutes before the ZD-99 has warmed up from room temperature (20 °C) to its maximum temperature (380 °C). After about five minutes the point of the soldering tip is at a temperature of 350 °C, high enough to start soldering.

|

| The warm-up time of the ZD-99. (© 2020 Jos Verstraten) |

At the tip of a soldering iron absolutely no static voltage should be present, as some parts cannot withstand it. The tip must therefore always be on earth potential. We have measured the resistance between the point of the soldering tip and the earth contact in the mains plug. For such measurements, our milli-ohm meter AE20218 is ideal! With our iron, this meter gave a value of 0.130 Ω at a measuring current of 100 mA.

A practical test

We set the potentiometer of the ZD-99 to the black line between the zones of 350 °C and 450 °C and timed when we could solder. After 3 minutes and 25 seconds the lead-containing solder melted on the point of the soldering tip. After 4 minutes and 6 seconds we could start soldering in series.

75 W soldering station